about us

In the competition with other auto parts manufacturers, the company has gradually built a strong core competitiveness by virtue of the advantages of nearby supporting facilities and quality services, established long-term cooperative relations with many large automakers, and continuously obtained new projects of various well-known brands and realized mass production support.

Reading light fully automatic assembly line

Reading lamp fully automatic assembly production line, short product production cycle, only 25S from product assembly to off the line; fully automatic and with error-proof identification, it can automatically correct and take photos of product color, missed installation, multiple installations, product surface defects, etc., mainly supplied to GM, a total of 60 parts configuration.

SMT patch line

SMT patch refers to the abbreviation of a series of processes processed on the basis of PCB, and PCB (Printed Circuit Board) is a printed circuit board. SMT stands for Surface Mount Technology (short for Surface Mounted Technology) and is one of the most popular technologies and processes in the electronics assembly industry.

BMW coated parts automatic production workshop

BMW-G08&G28 chair back panel automatic production line has the characteristics of reasonable layout, integration of digitization and intelligence. The automatic welding process leads the level of the same industry, and the automatic coating adopts advanced equipment of international well-known brands, in order to manufacture high-quality chair back panels, provide customers with high-quality products and services, and comprehensively enhance the comprehensive competitiveness of the coating process.

Spot welding robot workstation

The main core equipment such as spot welding robot workstation, robot, spot welding system has reliable performance, and the peripheral auxiliary non-standard equipment is convenient to operate, which can ensure the safe, reliable, efficient and economical operation of the production line. High-performance robots and system software specially tailored for spot welding applications, which can be compatible with spot welding of more than 500 products, reducing the need for labor for spot welding.

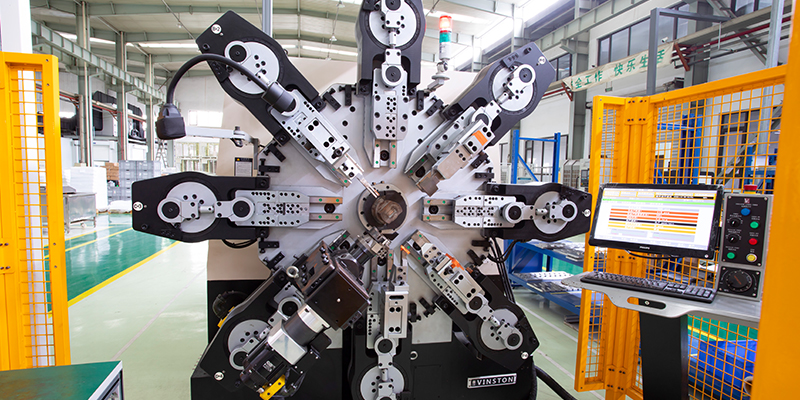

3D multi-axis bending machine

The 3D multi-axis bending machine refers to the flexible processing of flat wire materials according to the needs of parts through a variety of special tool head switching. The equipment has reasonable layout and strong free debugging, and can edit the material according to the needs to cut, twist and bend, and a single part can be quickly and automatically processed, suitable for most of the non-welded busbar production work.

Robot winding machine

Robot belt winding machine refers to according to the needs to place material belt to be winded on the winding machine head, the robot can according to the the winding part trajectory use insulation tape or other required materials to wind the parts, through the editing of the robot trajectory to achieve the seamless winding for traditional winding difficulties of corners, bending, flange , to reduce the winding process on the demand for labor.